The home hot water heater is usually too far from some of your hot water taps, so you have to open the tap and let the water run, wasting it, until the not-hot water standing in the pipe gets replaced by fresh hot water.

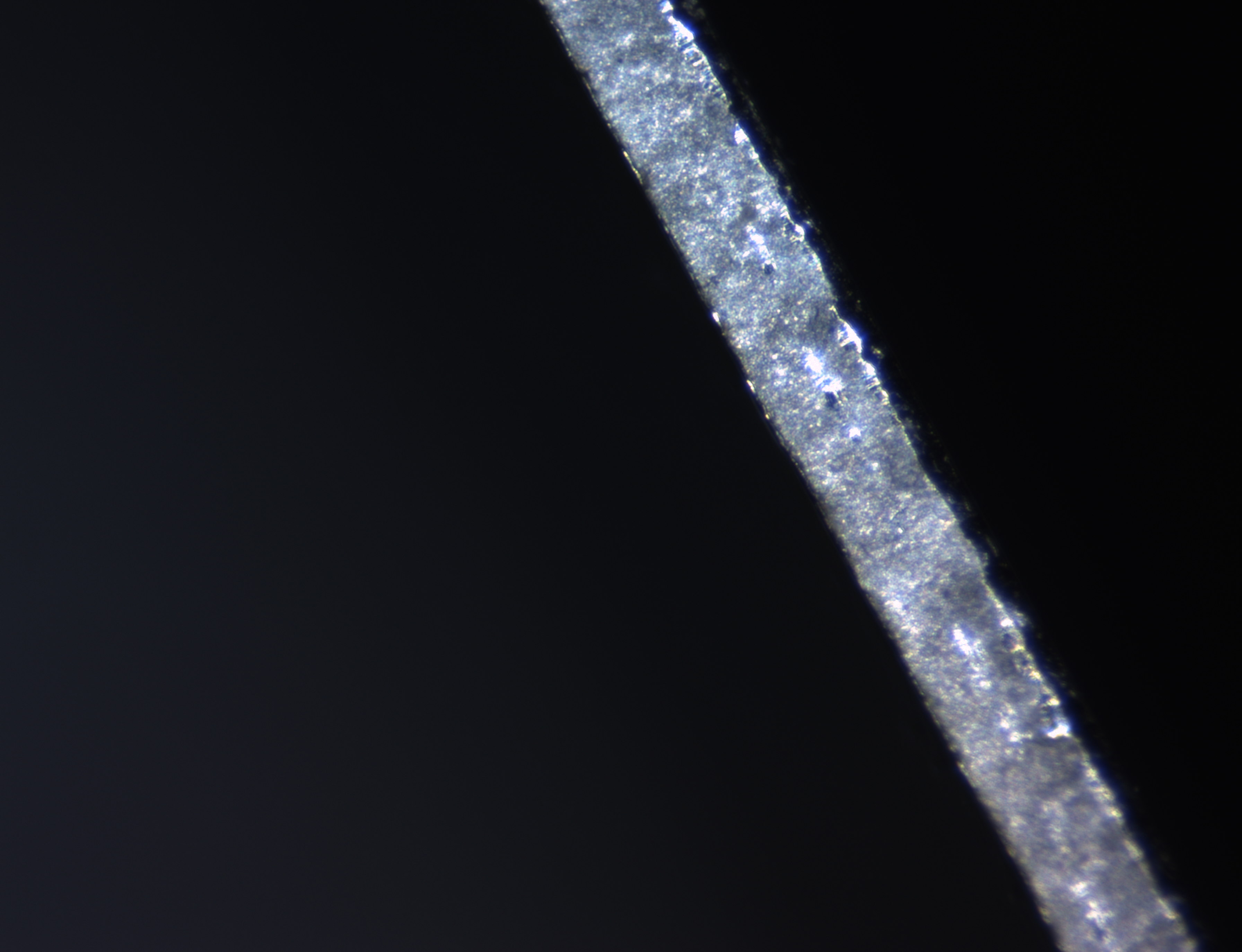

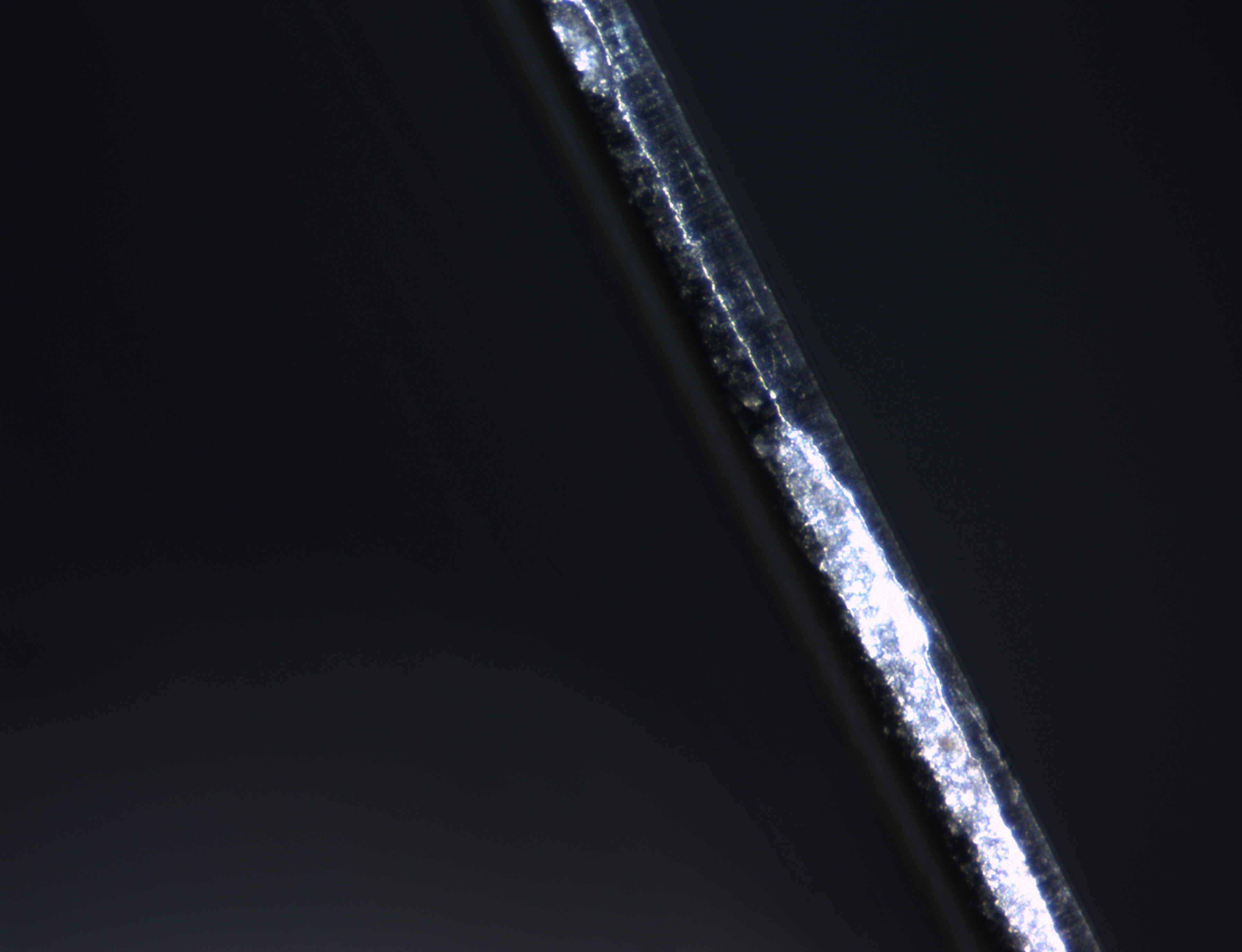

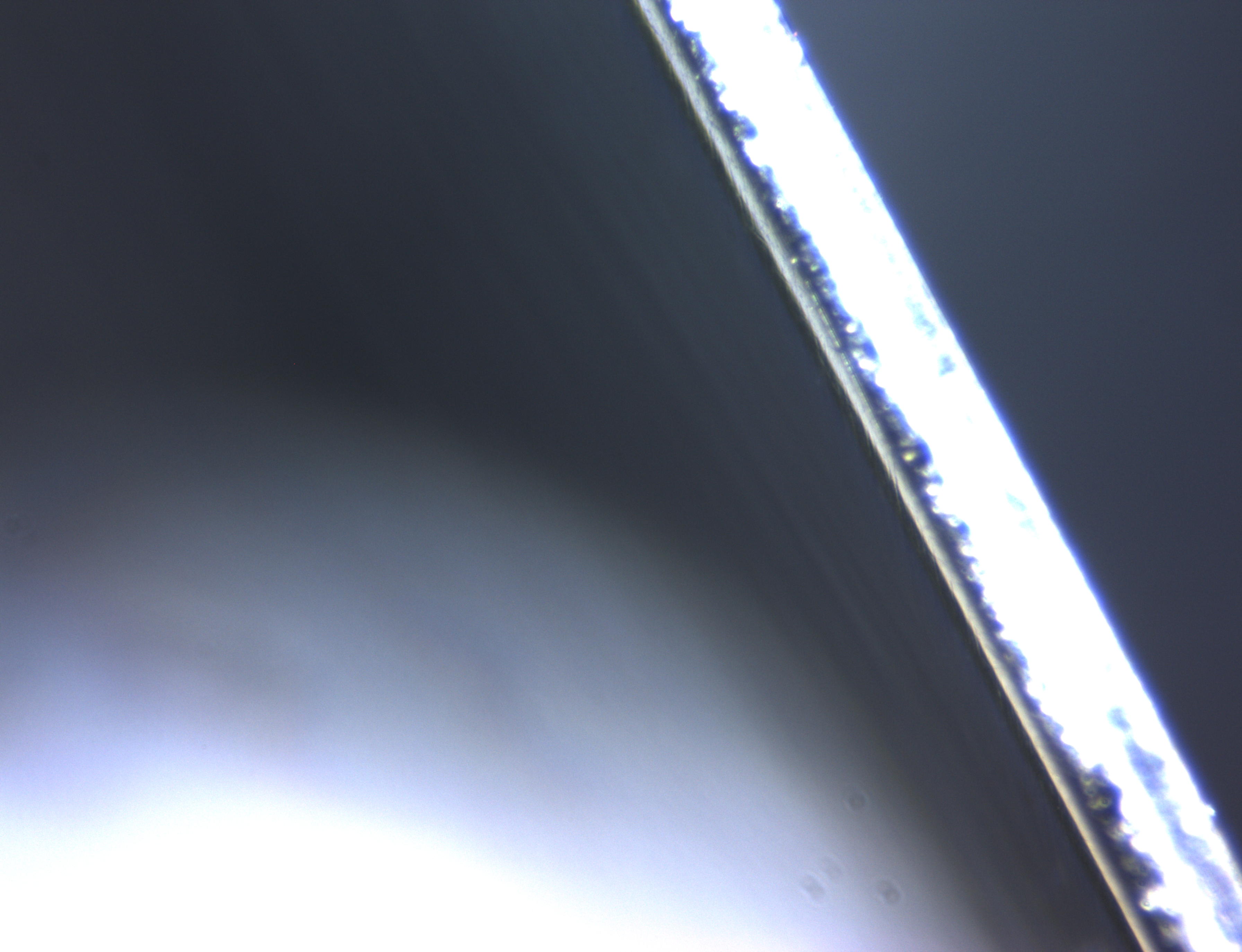

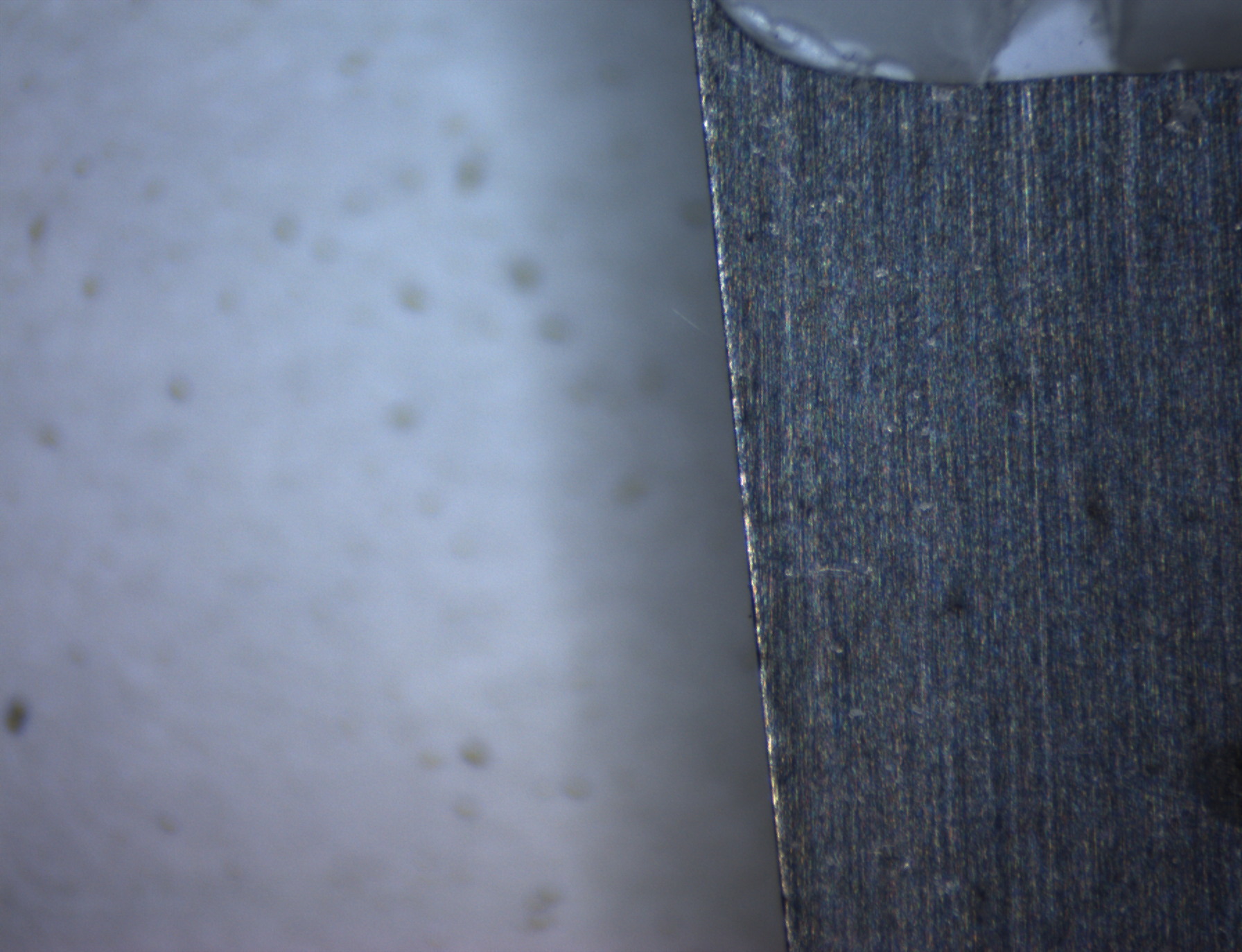

In new construction or remodels, the best solution is usually a small (say 3/8”) copper tube (or maybe PEX) from the most remote tap back to the cold water inlet of the hot water heater, through a quiet low-power recirculating pump that runs continuously. You don’t want a fast pump here, because too-rapid water motion causes the white mineral deposits that line copper pipes to erode away, exposing raw copper, which can be hazardous when it dissolves into the water. That could also promote leak formation.

The weak point may be that several taps are too far from the main circulating loop of hot water, so some will still require running the water for a while to get it hot. That can be avoided in a new design by routing the hot water loop so that none of the branches to taps are very long. For a retrofit, running additional tubes from the worst ones back to the pump. If you are lucky, enough water will flow in each branch to solve your problem.

The hot-water pipes and the recirculating tubes should be insulated, of course, so as not to waste heat.

Existing construction that wasn’t well designed

I recently moved to a villa in a retirement community that was not designed with hot water in mind. Instead of a dedicated return tube, they installed a pump on the hot water tank that raises the pressure of the hot water slightly, and under the remotest bathroom sink there is a temperature sensitive valve that lets water flow from the hot pipe to the cold whenever the hot water is cooler than the valve’s set point. (See Watts Premier Instant Hot Water Recirculating Pump System with Built-In Timer.)

That sounds good initially, the pump is quiet, and it does work, but it has a consequence: the cold water pipe is full of hot water too. Both the hot tap and the cold tap give you hot water, unless you run the cold for a long time. Not what you want for drinking or taking pills.

The manufacturer recognized that this is problematic, so they added a fancy mechanical timer that lets you choose, for each 15-minute interval in the 24 hour day, whether you want the timer to run or not: so you can schedule when in the day you want both taps to give you hot, or both give you cold; of course, you can always run the one that’s wrong until it’s right, but that wastes both water and time, so it’s not a pleasant solution.

There are other surprises too. For example, if you take a shower, there’s no cold (or hot) water to temper the hot (or cold) unless you let the water run a long time. If your water is too hot, you could get scalded if you jump in without checking—you can’t just add more cold as you might expect, because there isn’t any yet.

I prefer having hot water quickly, so I let the pump run always. It’s good for washing hands, but bad for drinking, taking pills, or brushing teeth.

I solve the cold problem by keeping a water glass full of cold (ok, room temperature) water sitting near the sink. I fill it after flushing the toilet, which uses up all the hot water that had been returning in the cold pipe, so I get cold water without much delay.

But things like to grow (or collect) in room temperature water, so you have to change the water frequently and wash the glass.

To me, this seems like an awful lot of trouble just for saving perhaps 40’ of tubing.

New construction ought never make this blunder.