A few years ago I purchased an iSesamo tool. It’s very handy for opening things that weren’t meant to open, like snap-together plastic housings. It is very thin flexible springy polished stainless steel, with useful bevels and curves at the ends and a molded-on handle in the middle to protect you from the thin edges.

I recently discovered it’s also great for prying 3D prints off the build plate of a plastic-filament extruder style of printer.

The tool is so handy that I found I often had left it “somewhere else”, so I decided to buy a few more to make sure I’d usually have one handy.

But this week I had a terrible time getting a 3D print loose. I blamed it on new-to-me material (PLA) on a new-to-me bed coating (http://BuildTak.com) on a new-to-me bed (glass, heated, removable—http://www.bctechnologicalsolutions.com). The iSesamo wouldn’t get between the printed part and the BuildTak, and when I pressed harder it dove down through the BuildTak and plowed a hole in it, and permanently bent the iSesamo! I’ve bent the original iSesamo very severely many times before without ever having it become permanent, which amazes me, but that’s now what I expect.

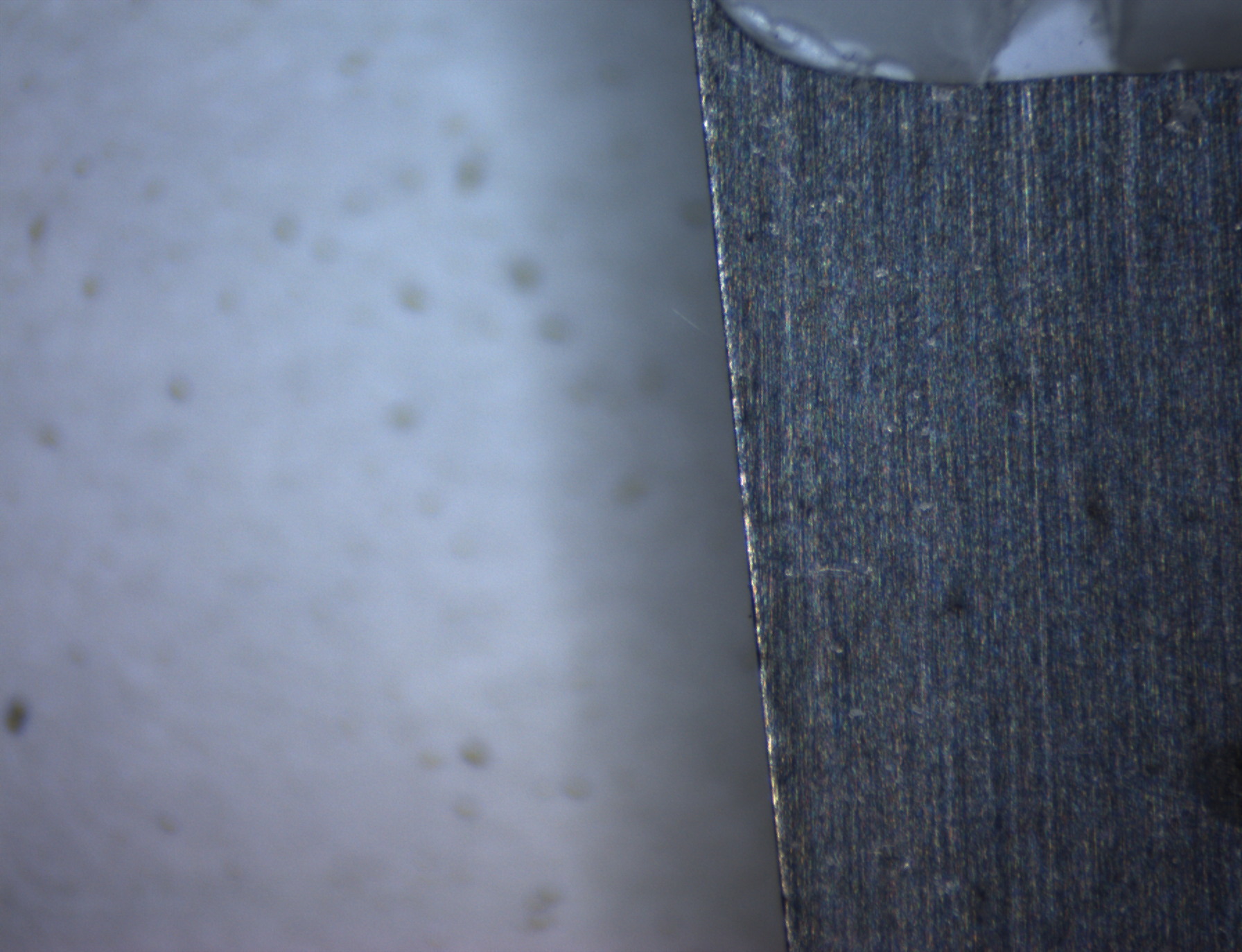

Then I took a more careful look at the new iSesamo, and discovered it’s not like the original one. Its molded handle is thinner, .135″ compared to .160″, and its edges are not smoothly tapered but square and sharp, like metal freshly stamped from a sheet. The original surely was also stamped from a sheet, but it must have been tumble-polished or something, because its edges are gently tapered and smooth. One of those sharp edges caught in the BuildTak and pulled the tool right down into and through it, where the original iSesamo would have sought out the weaker plane between BuildTak and PLA part and followed it. I did use the original for further removal attempts, and indeed that’s how it behaved. You are holding it at a shallow angle to the flat build plate, and pressing down, and the thin metal end gets parallel with the plate and guides itself along very smoothly.

So what’s the deal? Why are the new ones (all 3) different? Is it just a bad batch, or is it a new cost-lowering approach by someone who didn’t really understand what made it a great and useful tool?

I wondered for a bit whether it is my use of the tool that wore it smooth and polished, but I’m pretty sure that’s not the case, because the smoothness extends to regions of the blade near the handle that I probably have not used.

I took some microscope pictures to try to understand and describe the problem. Note that the low magnification pictures all use the same magnification, and the high magnification pictures do also, so the narrowing of the edge in the original tool is really a measure you can compare with the edge of the new tool.

Here are the photos:

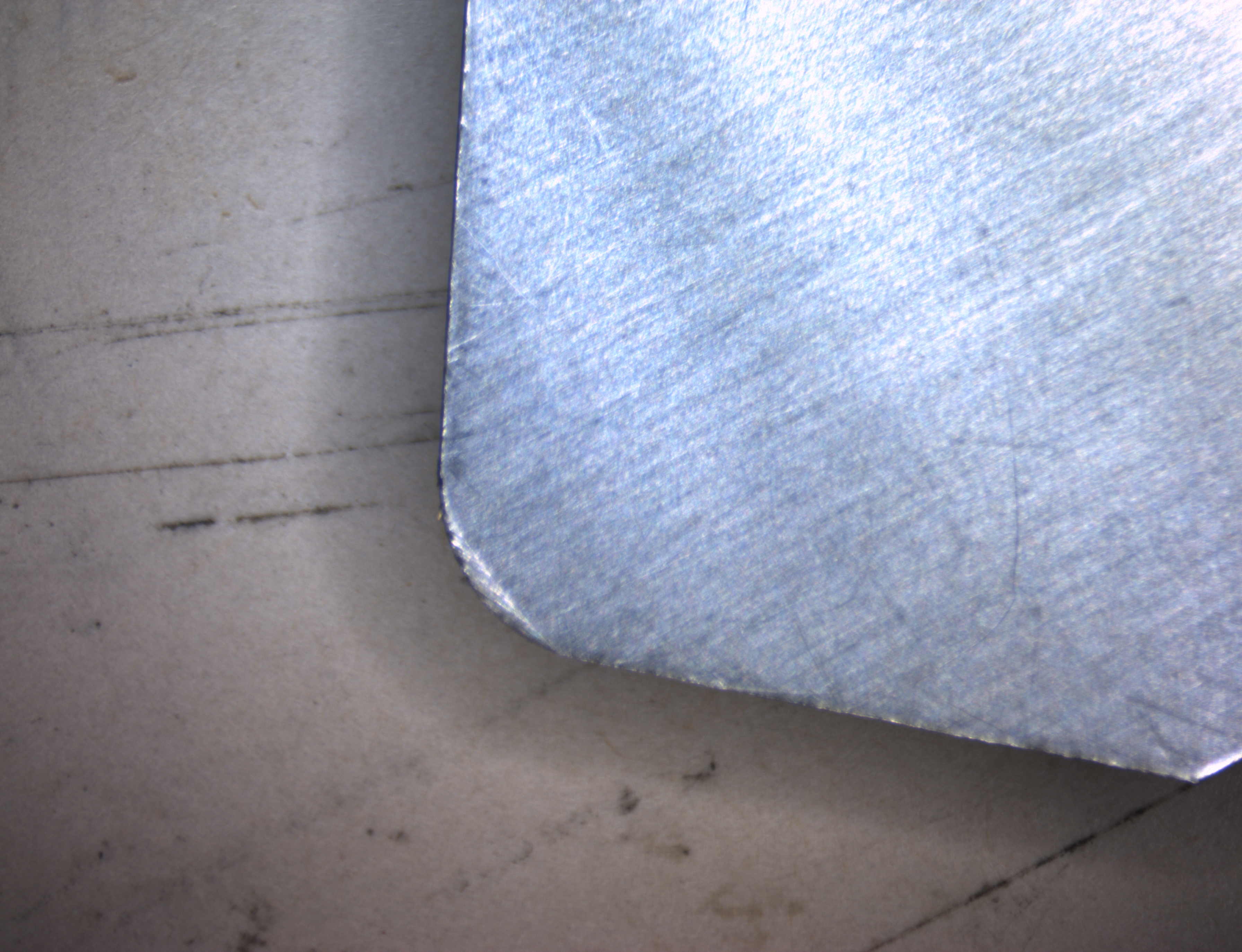

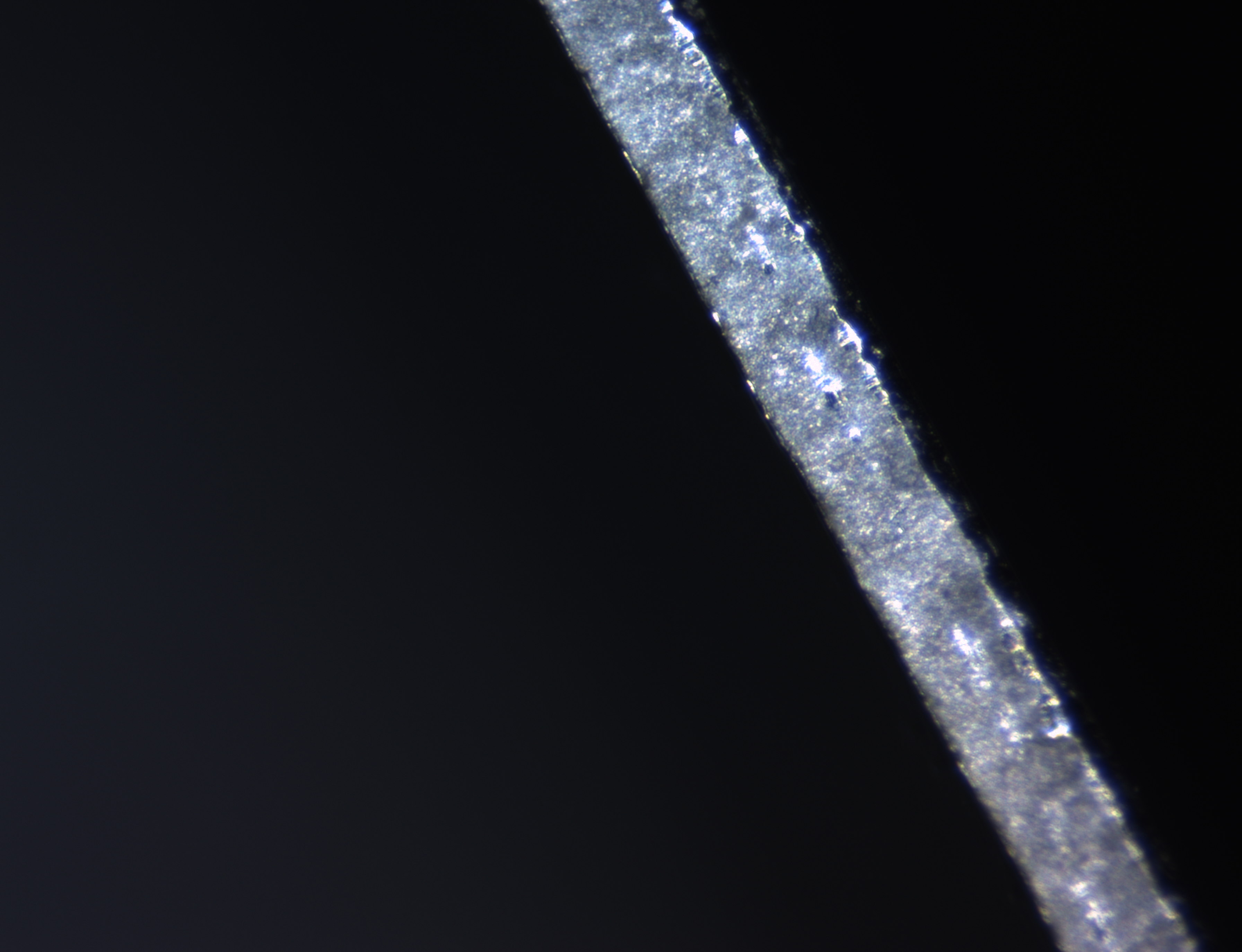

New tool, low magnification, flat view

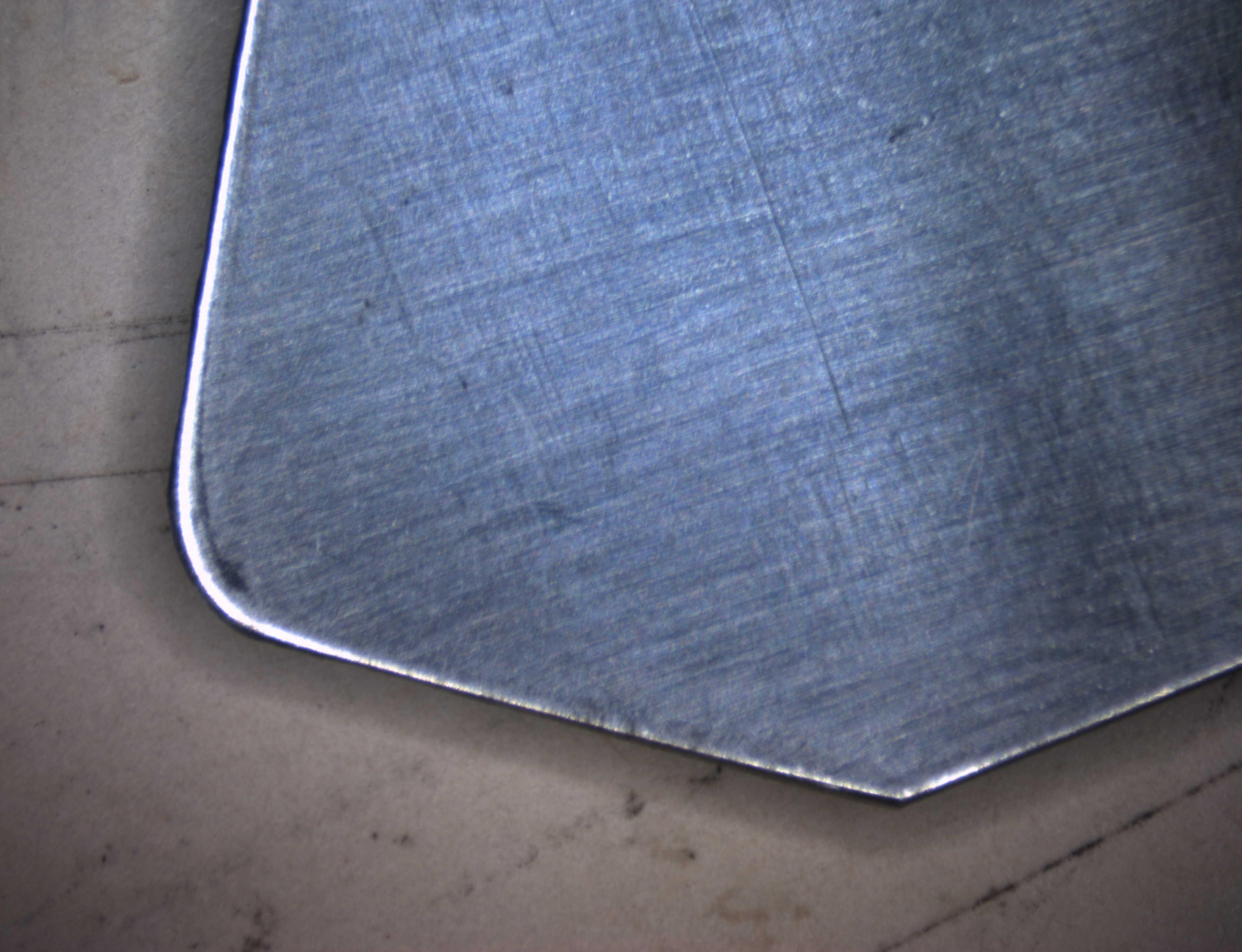

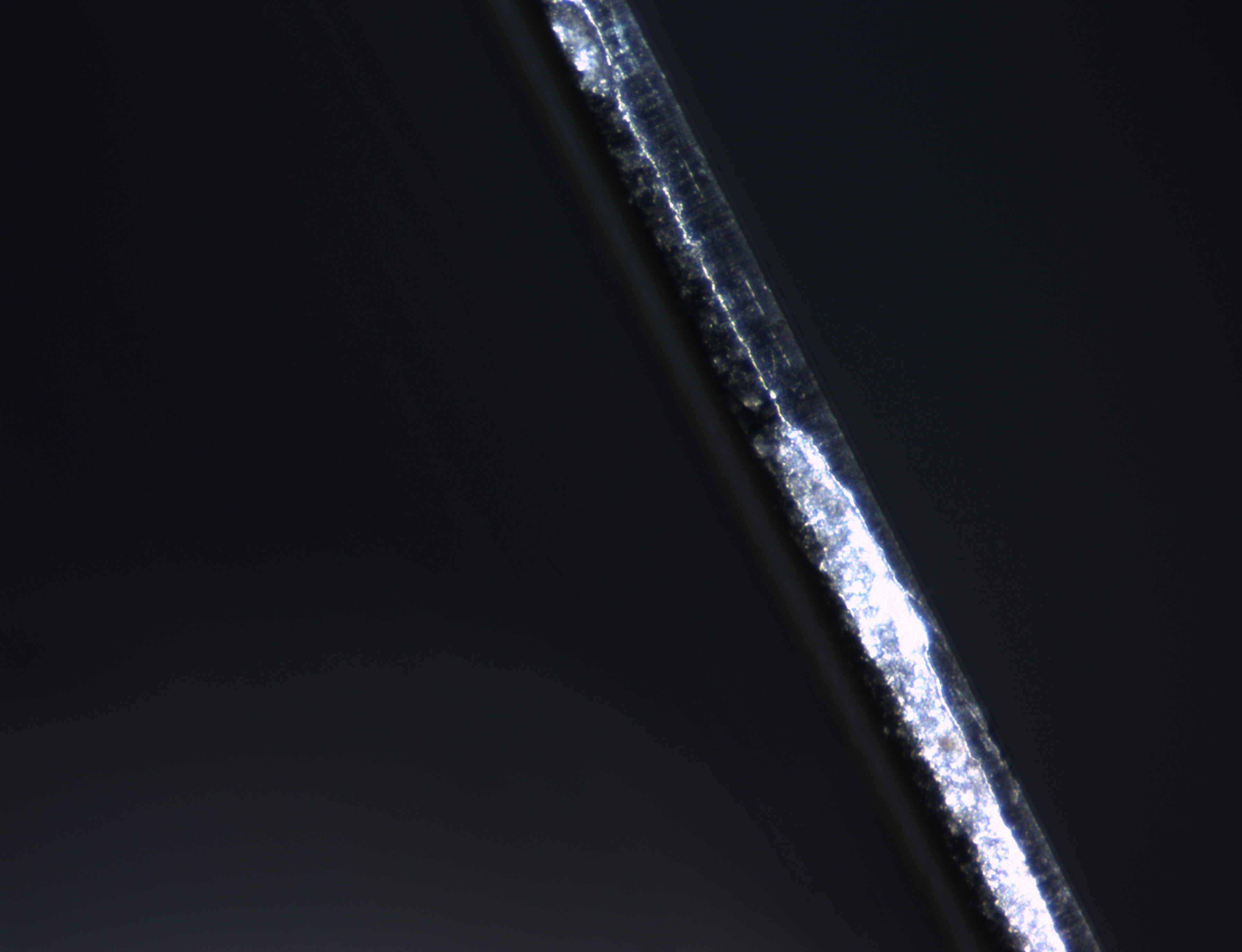

Original tool, low magnification, flat view

New tool, low magnification, another flat view

Original tool, low magnification, another flat view

Notice how the new edge is just squared off from being stamped out, while the original is smoothed and sharp-ish.

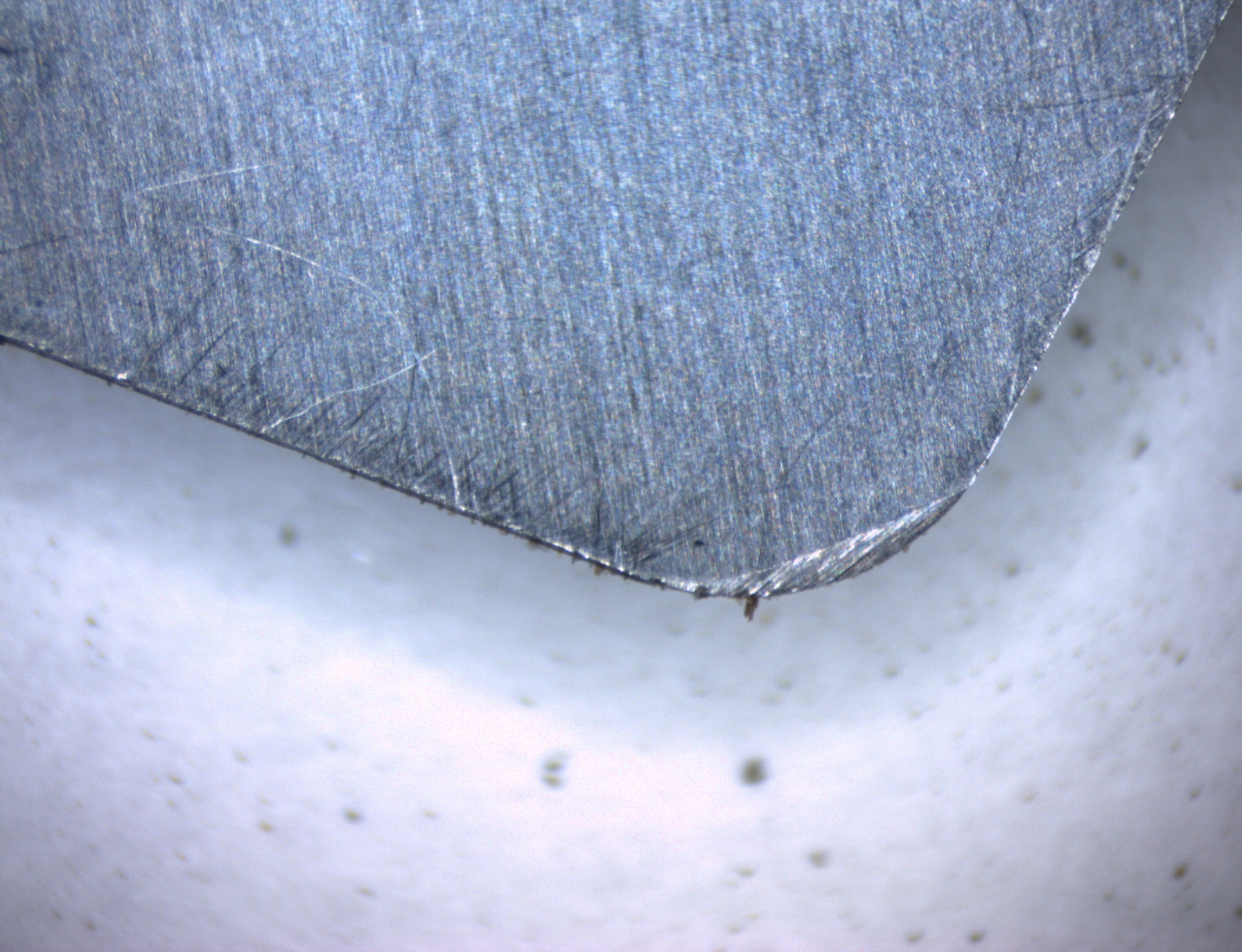

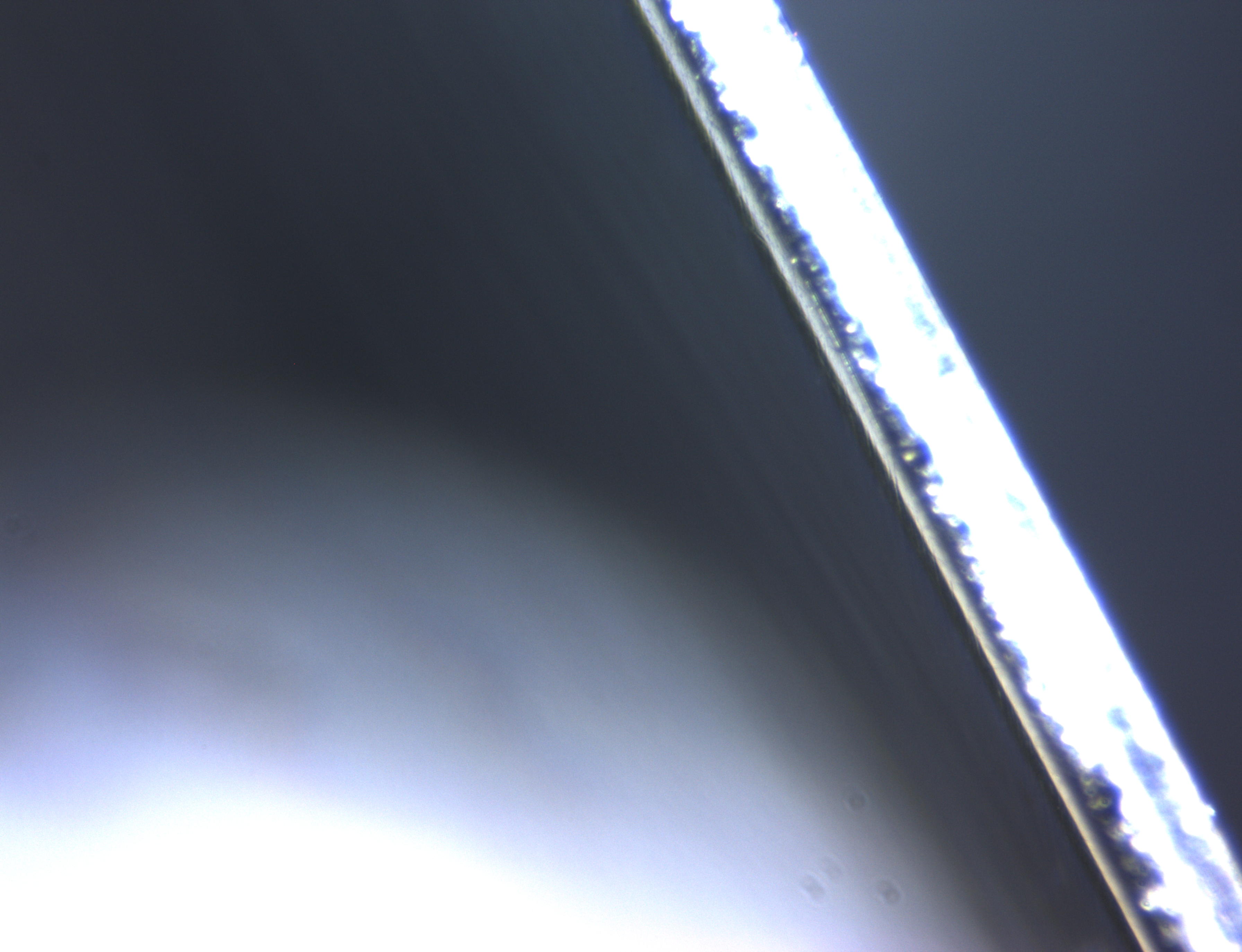

New tool, high magnification, edge view

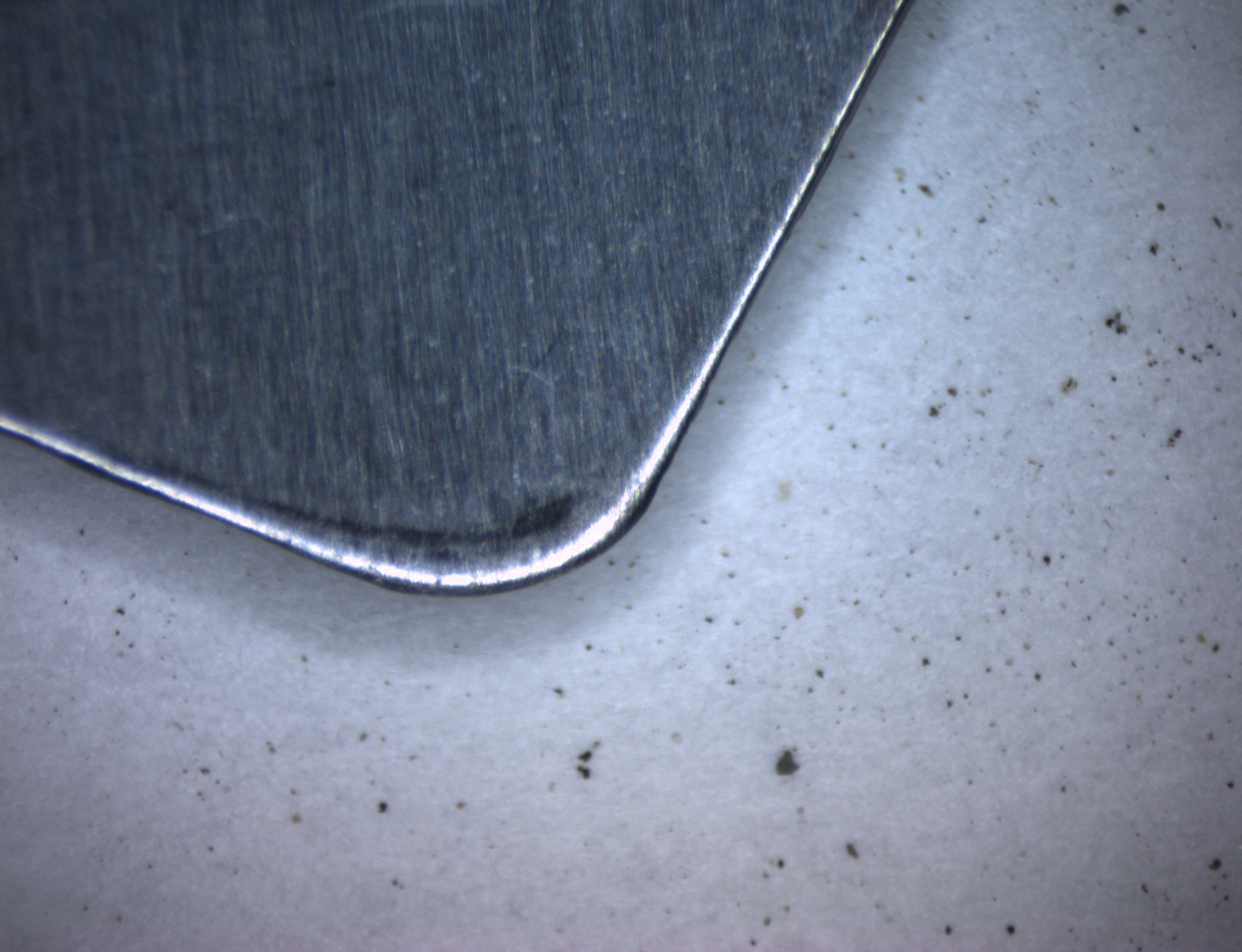

Original tool, high magnification, edge view

It’s hard to show, but one of them looks like there was a surface layer in the original that’s different from the material in the body of the blade, kind of a Damascus Steel layering, to get the best properties of two different alloys.

Original, high mag, just-past-edge view, layers. Looks like smooth outer layers over hard mid layer in tool. Focused below sharp edge.

New, low mag, edge near handle. No polishing or smoothing.

OK, I never heard back from the company, so I finally took a fine diamond hne and spent some time grinding off the sharp lips, and used a plier to straighten the bent one, so I now have 4 useable ones.

But it’s a shame the quality of the product slipped so far. Must be new management.